Label Rewinders and Dispensers

If your labeling station is slowing down because of liner waste, inconsistent roll tension, or time-consuming peel-and-apply, label rewinders and dispensers are usually the easiest upgrade you can make—without changing your labeler.

As an automated labeling distributor, BPM Systems helps packaging teams choose the right accessories for their workflow—so your labels feed cleanly, your operators move faster, and your line stays organized.

Why Label Rewinders and Dispensers Matter on Real Packaging Lines

These tools aren’t “nice to have” when production ramps up—they prevent the small problems that turn into daily downtime:

- Liner backing piling up and creating jams

- Roll tension drifting and causing misfeeds

- Operators losing time peeling labels by hand

- Messy workstations that slow down changeovers

- Label rolls that aren’t prepped consistently for application

Types of Label Rewinders & Unwinders

Standard Tabletop Label Rewinders

Tabletop rewinders are compact units built for small to mid-volume operations that want clean, consistent roll take-up directly from desktop label printers. They’re designed for smooth, quiet operation with adjustable torque to prevent tearing, telescoping, or misalignment—so rolls are ready for use instead of needing manual cleanup.

Best fit: offices, craft production, small manufacturers, print-on-demand setups.

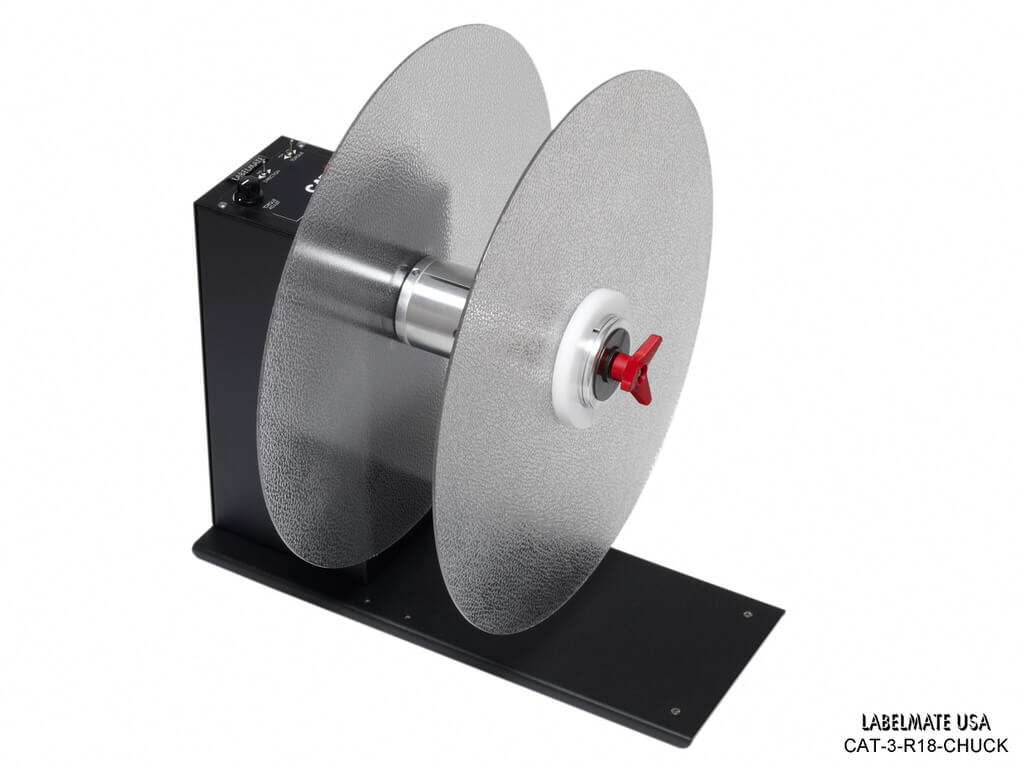

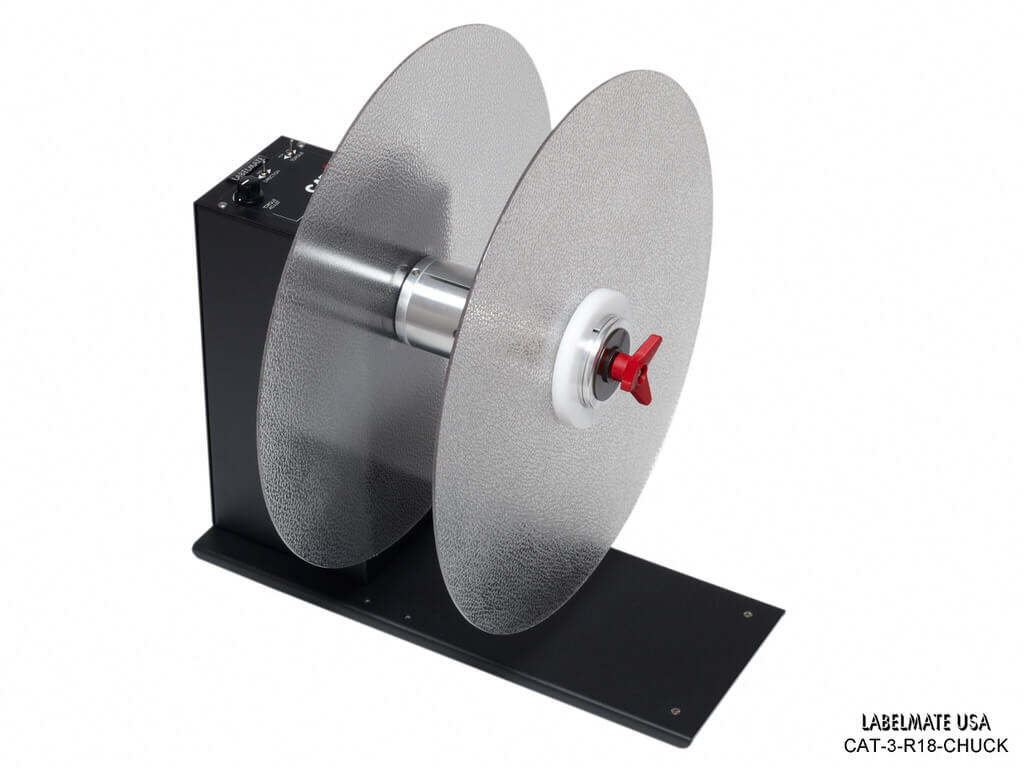

Heavy-Duty & High-Torque Rewinders

For larger roll diameters, wider labels, and heavier stocks (film, foil, laminated materials), high-torque rewinders are the workhorse option. They’re built for continuous operation and stable tension control—ideal when you’re running longer print jobs or producing batches that need consistent roll quality.

Best fit: industrial packaging, pharmaceutical traceability runs, higher-volume bottling lines.

Adjustable Core Holders & Specialty Rewinders

If you switch between different core sizes or need more flexibility, adjustable core holders let you change between common cores (like 1”, 1.5”, and 3”) without extra tooling. Specialty rewinders also support use cases like bi-directional rewinding, inspection/rework workflows, and slitter-rewinder setups for narrowing rolls.

Best fit: flexible packaging, rework lines, contract packaging operations.

Label Unwinders & Roll Feed Systems

Unwinders are all about smooth, stable feed into printers or applicators. They help prevent feed errors and tension spikes (which can cause print issues and premature wear). High-capacity unwinders are especially useful when your roll supply exceeds what a printer can handle internally—so you can run longer with fewer roll changes.

Best fit: continuous printing runs, wide-format labeling, serialization printing.

Integration With Dispensers and Labeling Systems

Ready to Upgrade?

Label Rewinders and Unwinders

Label rewinders and unwinders keep label rolls controlled before and after printing or dispensing. They’re commonly used to collect liner backing, rewind printed labels into clean rolls, or feed material smoothly into downstream stations.

Roll Label Rewinder Machines

A roll label rewinder machine winds labels (or liner) into a tight, consistent roll so your workstation stays clean and your material stays manageable—especially helpful for batch printing or longer runs.

Automatic Label Rewinders for Continuous Production

Automatic rewinders are ideal when labels are printed or dispensed continuously and you want tension control without constant operator adjustment. They help prevent slack, telescoping rolls, and misfeeds that cause stoppages.

Label Dispensers

Label dispensers “peel and present” labels so operators can apply them faster and more consistently. This is one of the simplest ways to speed up manual labeling without jumping straight to a fully automatic labeler.

Manual Label Dispensers

Manual dispensers are a great fit for occasional labeling, short runs, or low-volume packaging areas where you want clean peel-and-present without power.

Rewinder vs. Dispenser: What’s Right for You?

If you’re choosing between the two, here’s the quick rule:

- Choose a dispenser when your bottleneck is peeling and applying labels faster.

- Choose a rewinder when your bottleneck is roll/liner management and tension control.

Many operations use both: a dispenser up front to present labels cleanly, and a rewinder behind it to collect liner backing and keep the area tidy. (This “rewinder vs. dispenser” comparison is a recommended H3 cluster in your sitemap strategy.)

Ready to upgrade with BPM Systems?

Redwinders and dispenser machines provide the speed, consistency, and reliability needed for modern manufacturing operations. BPM Systems works with trusted equipment partners to help manufacturers select, integrate, and support labeling solutions that align with real production goals.

Contact BPM Systems to evaluate the right machine for your operation.