Rewinder Label Machine Systems for Precision Roll Handling

BPM Systems supplies high-performance rewinder label machines engineered for clean, accurate, and efficient label roll management. As an authorized distributor of LabelMate solutions, we offer industry-trusted tabletop rewinders, heavy-duty rewinders, unwinders, and slitter-rewinder hybrids designed to keep production lines organized, consistent, and inspection-ready. Whether you’re rewinding labels straight from a printer or managing large-format rolls, our systems provide smooth torque control, stable tension, and quiet operation for professional results.

Types of Label Rewinders & Unwinders

Standard Tabletop Label Rewinders

These compact rewinder label machine units are ideal for small to mid-volume operations that need clean, consistent roll take-up directly from desktop label printers. Tabletop rewinders are engineered for smooth, quiet operation with adjustable torque that prevents tearing or telescoping—ensuring perfect roll alignment for downstream use.

Best fit: Offices, craft production, small manufacturers, print-on-demand setups.

Heavy-Duty & High-Torque Rewinders

High-torque rewinders support larger roll diameters, wider labels, and heavier materials such as film, foil, or laminated stocks. Designed for continuous operation, these systems maintain stable tension control for long print runs, batch production, or industrial labeling environments.

Best fit: Industrial packaging, pharmaceutical traceability runs, high-volume bottling lines.

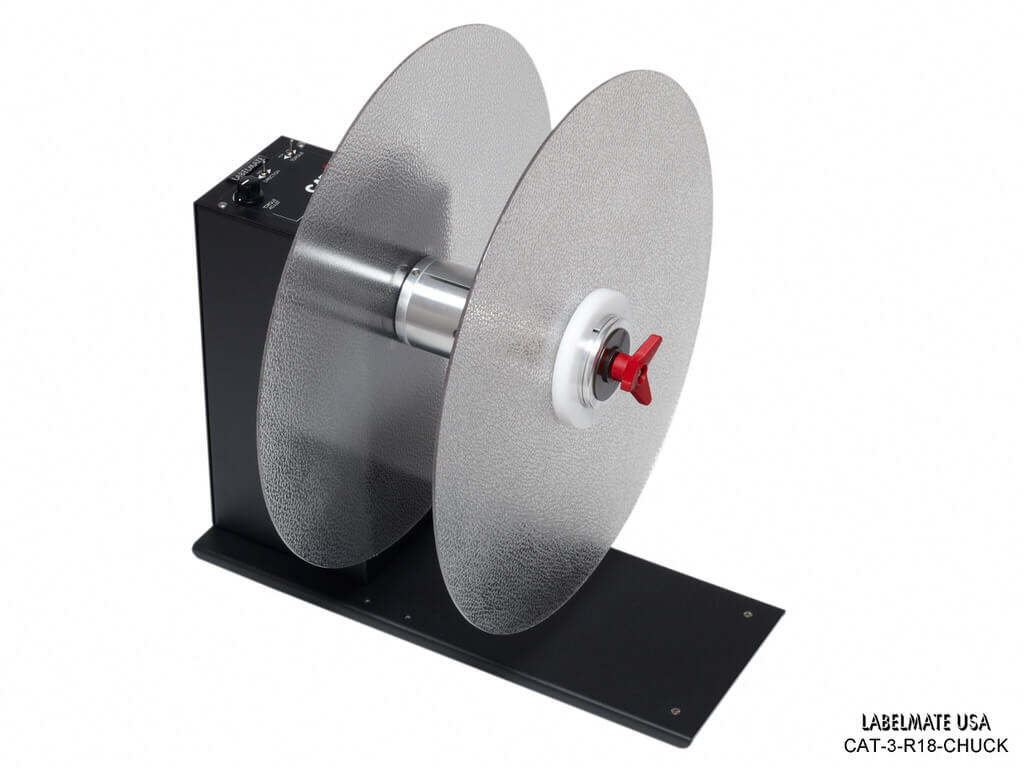

Adjustable Core Holders & Specialty Rewinders

These machines are designed for operations that require multiple core diameters, bi-directional rewinding, label inspection, or roll correction. Adjustable core holders allow switching between 1″, 1.5″, and 3″ cores without additional tooling. Specialty models include slitter-rewinders for narrowing rolls and inspection rewinders for quality-control workflows.

Best fit: Flexible packaging, rework lines, contract packaging.

Label Unwinders & Roll Feed Systems

Unwinders deliver smooth material feed into printers or applicators, preventing feed errors, tension spikes, and printer wear. High-capacity unwinders are essential when your roll supply exceeds your printer’s built-in capacity, enabling longer production cycles and improved efficiency.

Best fit: Continuous printing runs, wide-format labeling, serialization printing.

Integration with Your Labeling Systems

A rewinder label machine integrates seamlessly with desktop printers, print-and-apply systems, semi-automatic bottle labelers, or full automation lines. Proper integration ensures synchronized speed, clean take-up, and minimized downtime.

Ready to Upgrade to Label Rewinders and unwinders?

Choosing the Right Rewinder Label Machine

Core Size Compatibility

Does your operation switch between product lines or label suppliers? Adjustable core holders offer maximum flexibility

Maximum Roll Diameter

Larger rolls reduce changeover downtime but require stronger torque and weight capacity.

Speed & Torque Requirements

Match rewinder speed to your printer output—or choose a variable-speed unit for precision control.

Material Type

Paper labels, film labels, metallic substrates, or pressure-sensitive adhesives may require different tension configurations.